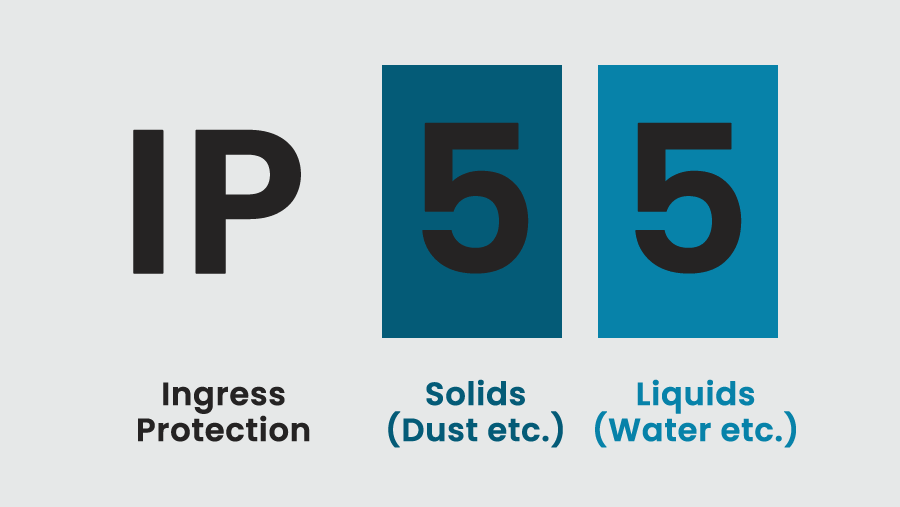

Diving into the domain of air-compressor industry, one encounters a myriad of inherent terminologies and classifications. One such pivotal classification is the IP (Ingress Protection) rating of a motor, a measure of the motor’s resistance to dust and water ingress.

You can click on any section that you interest to get there quickly.

What is the Motor IP Rating?

The motor IP rating is a standard that provides information about how well the motor is protected against solid and liquid intrusions.

IP is an abbreviation for “Ingress Protection”.

IP ratings are defined by the International Electrotechnical Commission (IEC as per IEC 60034-5:2020). It classifies the degrees of protection provided against the intrusion of solid objects (including body parts like hands and fingers), dust, accidental contact, and water in electrical enclosures.

An IP rating is specified by two digits. The first digit, ranging from 0-6, represents the level of protection that the enclosure provides against access to hazardous parts and the ingress of solid foreign objects.

The second digit, ranging from 0-8, symbolizes the level of protection the enclosure provides against the harmful ingress of water.

For example, a common IP rating for an electric motor might be IP55, where the ‘5’ shows that the motor is protected against dust, but not entirely dust-tight, and the second ‘5’ that the equipment is safeguarded against water jets from any direction. The higher these numbers, the more robust the protection.

What Do the Numbers in the Motor IP Rating Mean?

Dust Protection Level

The first digit of the IP rating represents the dust protection level, and ranges from 0 to 6, with a larger number indicating stronger dust resistance:

– 0: No protection.

– 1: Prevents the entry of solid objects larger than 50mm.

– 2: Prevents fingers or other objects not exceeding 80mm in length from reaching electrical or moving parts.

– 3: Prevents tools or wires above 2.5mm in diameter from reaching electrical or moving parts.

– 4: Prevents wires or strips above 1mm in diameter from reaching electrical or moving parts.

– 5: Dust-protected. Dust may enter, but not in amounts sufficient to affect the normal operation of the motor.

– 6: Dust-tight; completely prevents dust entry.

Water Protection Level

The second digit represents the water protection level and ranges from 0 to 9, with a larger number indicating stronger water resistance:

– 0: No protection.

– 1: Prevents harmful effects from water droplets falling vertically.

– 2: Vertical water droplets will not have harmful effects when the motor is tilted at 15 degrees.

– 3: No harmful effects from water sprayed within a 60° angle.

– 4: Prevents harmful effects to equipment inside the enclosure from splashing water (from any direction).

– 5: Prevents harmful effects to equipment inside the enclosure from water jets (from any direction).

– 6: Prevents sea wave impacts or high-pressure water jets.

– 7: After the motor is submerged in water under specified pressure for specified time, the water amount inside the motor should not reach a harmful degree.

– 8: The motor can be submerged for a long time under conditions specified by the manufacturer.

– 9: High-temperature high-pressure water jets sprayed on the motor casing from any direction should not have harmful effects.

Extra Letters

In addition to the above common grades, there are some supplementary letters in the motor IP rating:

– H: For high voltage equipment

– M: The waterproof test was conducted when the moving parts of the equipment (such as the rotor of a rotating motor) were in motion.

– S: The waterproof test was conducted when the moving parts of the equipment (such as the rotor of a rotating motor) were stationary.

– W: Provides additional protection or processing to apply to specified weather conditions.

Moreover, there are also special environment codes for motors which further define the conditions under which the motor can function optimally:

– G: For use in the plateau

– H: For maritime application

– W: For outdoor use

– F: Corrosion-resistant

– T: Tropical use

– TH: For humid and hot climate

– TA: For dry and hot climate

Understanding these codes and their implications can play a significant role in choosing a motor that is well-suited to the operational environment, thereby enhancing the longevity and performance of the motor.

What IP Rating Motor Should My Air compressor be Equipped with?

When choosing a motor for an air compressor, it’s generally recommended to use a motor with an IP rating of IP23. This level of rating offers a degree of protection against dust and water, suitable for most industrial environments.

Moreover, for marine applications, equipment usually requires a higher IP rating due to the harsher working conditions.

Based on marine electronics standards, choosing a motor with an IP rating of IP65, IP66, or IP67 is recommended. These ratings indicate that the motor can resist water intrusion to varying degrees, from water jets (IP65) to temporary immersion in water (IP67). This enhances reliability and longevity in maritime environments.

However, it’s always vital to consider the specific conditions and requirements at your site before making a final decision. Consult professionals if possible to make an informed selection.

What is ppm in Air Quality? The key Data of Air Compressor

Understanding ppm in air quality enables industries to monitor and maintain optimal air purity levels, minimize contamination risks.

By selecting air compressors with appropriate specifications and monitoring ppm levels effectively could ensure the application safety and efficiency of compressed air systems.