Air compressor room design is not a very simple matter and usually requires a team with rich experience to carry out it.

But, before that, we can get an overview of it and what to consider. This may be helpful for your project.

You can click on any section that you interest to get there quickly.

What is the Air Compressor Room?

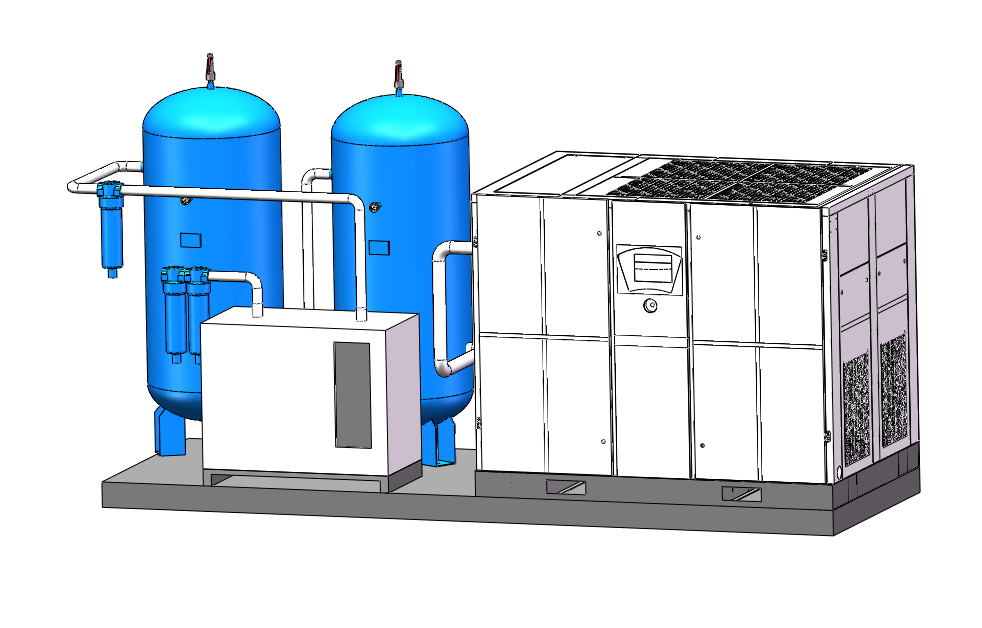

The air compressor room is a dedicated space that houses all the essential components of an air compressor system.

Every air compressor room is unique, as its setup mostly depends on the requirements of the specific application it serves. From small businesses to large industrial facilities, from healthcare to manufacturing sectors – an air compressor room plays an indispensable part in generating and managing compressed air.

What Equipment is Included in An Air Compressor Room?

The entire air compression system is relatively complex, especially when used in applications with high air requirements and large demand. It requires the participation of multiple devices and stable cooperation with each other.

In most compressed air station, the following equipment will be present:

Air Compressor

The heart of the system, it’s here that the air is compressed. Various models (screw, piston, rotary) and power ratings exist based on requirements.

Click to check Airpressa screw air compressors

Refrigerated Air Dryer

As a device working on a cooling principle, refrigerated air dryers reduces the temperature of the compressed air, causing the moisture to condense for efficient removal.

Desiccant Air Dryer

This type of dryer employs adsorbent material to remove moisture from the air. It’s especially useful when you need a lower dew point than a refrigerated dryer can provide.

What Is The Regenerative Desiccant Air Dryer? How Does It Work?

The regenerative desiccant air dryer play an important role in many important manufacturing industries.

When compressed air is received, the air dryer processes the air to achieve the conditions required for the application. Compared with refrigerated air dryers, what are the differences between regenerative desiccant air dryers? How does it work?

Air Receiver Tank

This acts as a storage space for the compressed air. It’s responsible for maintaining a consistent pressure in the system by reducing the frequency of the compressor’s on/off cycling.

Click to compressed air tank series

Air Filter System

With the atmosphere containing various impurities, the air filter system is vital. It cleans the compressed air by removing these impurities, thus enhancing the lifespan of the system and maintaining the quality of the air.

Click to compressed air filter series

Heat Recovery System

In addition, air compressors generate a significant amount of heat that typically goes wasted. A heat recovery system can harness this heat, converting it into useful energy that can be used for space heating, water heating, and process heat.

These components work harmoniously to create an efficient and effective air compressor system.

For most industrial applications, air compressors, refrigerated air dryers, air tanks, air filtration systems and piping make up the whole compressed air system.

In some special applications, such as pharmaceuticals, a desiccant air dryer may be required.

Working Pressure and Free Air Delivery (FAD)

Determining how much air flow your project or production requires involves a few important steps. Here’s a simple guide:

List Out Your Air Tools

Identify all the pneumatic equipment or tools your project will utilize. Remember that not all tools will operate at the same time, and not all will require a compressor.

Check CFM & PSI Ratings

Each tool has a specific Cubic Feet per Minute (CFM) and Pounds per Square Inch (PSI) rating showing the amount of air flow required for optimal functioning.

These ratings are usually described in the tool’s user manual or on an information plate located on the device.

In some areas, m3/min also be used to calculate air flow.

Click to check convert m3/min to cfm chart

Consider Simultaneous Usage

Consider the tools that might need to operate simultaneously. Sum up the CFM of these tools. This provides the minimum CFM your compressor should deliver.

Plan for Peaks and Downtime

Recognize that usage might peak at times, and also account for the fact that air tools don’t run continuously but rather in active cycles (for instance, a spray painter is not always ‘on’).

Include a Buffer

By adding a margin of about 30% to the calculated CFM, you ensure the compressor can handle the load even if requirements change slightly.

Please note that these calculations provide an estimation of air flow needs, and specific nuanced manufacturing setups might require more detailed analysis conducted by professionals.

What Is The Regenerative Desiccant Air Dryer? How Does It Work?

The regenerative desiccant air dryer play an important role in many important manufacturing industries.

When compressed air is received, the air dryer processes the air to achieve the conditions required for the application. Compared with refrigerated air dryers, what are the differences between regenerative desiccant air dryers? How does it work?

Indoor or Outdoor?

Now you have to consider whether to build your compressed air station indoors or outdoors. Although, in most cases, the air compression system is inside the room.

Outdoor Air Compressor Station

Benefits

Enhanced Ventilation: The outdoor setting provides abundant fresh air for cooling the compressor, reducing overheating risks.

Noise Control: Noisy operations of large industrial air compressors are less disturbing in an outdoor setting.

Space Conservation: Hosting the compressor outdoors frees up indoor workspace.

Disadvantages

Weather-Related Challenges: Outdoor units stand exposed to the elements, including extreme temperatures, which may affect performance and lifespan.

Increased Maintenance Needs: Potential for rusting, icing, and damage due to precipitation or dust necessitates regular maintenance.

Security Concerns: Outdoor units might be more exposed to potential theft or vandalism.

Indoor Air Compressor Station

Advantages

Protection from Elements: Indoor units are shielded from harsh weather conditions, reducing corrosion and other weather-induced damage.

Better Security: Indoor placement can provide extra security against theft or vandalism.

Ease of Maintenance: Indoor environments might aid in clean operations and maintenance activities.

Disadvantages

Limited Space: Indoor units can take up significant workspace, a downside for space-economic industries.

Ventilation Requirements: Indoor units require proper ventilation systems to avert overheating.

Noise Issues: Indoor compressors might elevate noise levels in the workspace, potentially affecting the working environment.

Space for an Air Compressor Room

Reserving sufficient space for an air compressor room involves various factors based on the type, size, and number of air compressors, as well as the cooling and ventilation system in place.

Size of Air Compressor

Logically, more substantial compressors demand more space. The room must accommodate not just the compressor unit or units, but also any additional equipment such as air dryers and filters.

Proper Ventilation

Adequate ventilation is critical to prevent overheating. The compressor room should ideally have an inflow and outflow of air, enabling a comfortable working temperature to be maintained.

Access for Maintenance

Remember, compressors require regular maintenance. Therefore, there should be enough room for servicemen to move around easily and perform their tasks.

Space for Expansion

If you plan to expand your operations in the future, keep some extra space in your compressor room.

Safety Protocols

Adhere to all safety norms such as clearance for fire exits, installation of necessary fire safety equipment and in some cases, accessibility for lifting equipment to move parts.

Air Quality in the Air Compressor Room

The quality of air in an air compressor room is fundamental both for the health and safety of employees and the prolonged efficiency of the air compressor.

Ensure clean air

Contaminants can be anything from dust and dirt to metallic particles and aerosols. The particulate matter can damage the compressor and degrade the quality of compressed air output.

Moisture Content

Air compressors naturally produce condensation during their operation. Too much moisture can lead to corrosion in the air compressor and distribution system.

The air dryer can help reduce moisture content in the air, maintaining air quality and preventing damage to the compressor and tools.

In addition, in the most cases, please avoid chemicals in the compressed air room.

What Is Pressure Dew Point? Why Is It So Important?

Pressure dew point is a key term that must be mentioned in the air compressor industry. It plays a vital role in the entire compressed air system, connected equipment and applications.

Different from atmospheric dew point, pressure dew point has more practical application significance. So, what is pressure dew point and why is it so important?

Pipe Connections and Distances

Designing the layout of pipes in an air compressor room involves careful planning to ensure efficient operation, easy maintenance, and safety.

Pipe Material and Diameter

The type of pipe material and its diameter can considerably affect the efficiency of your system. Commonly used materials include metal, such as black iron or copper, and plastics like PVC or HDPE.

Metal pipes can withstand higher temperatures and pressures but may corrode over time, while plastic pipes are more corrosion-resistant but may not be suitable for high-temperature applications.

The pipe diameter should be sufficient to maintain pressure and minimize energy loss.

Pipe Length and Distance

Minimize pipe length and bends as much as possible to reduce air pressure loss and minimize the energy requirement. If your air compressor room is large, consider whether the pipe lengths could be causing pressure drops in some parts of the system.

Maintenance Access

When planning the device and pipe connections, the future maintenance requirements should be considered. Leave enough room around critical junctions and gateways for easy maintenance or replacement work without disrupting the entire system.

Air Compressor Room Ventilation Design

As the whole air compressor system operate, they produce a significant amount of heat in the air compressor room.

A well-executed ventilation and cooling system helps in maintaining the operating temperature within permissible limits, thus ensuring optimal performance.

What Should be Careful in the Compressed Air System Design?

Click to view Airpressa’s compressed air system details and configuration. Understand the considerations in the design process.