Home » Industries »

Air compressor in Food and Beverage Industry

Air Compressors for Food and Beverage

Air compressors are indispensable assets in the food and beverage industry, contributing to the production of safe, high-quality products while ensuring compliance with industry regulations and standards.

Investing in the right air compressor tailored to the specific needs of food and beverage processing can enhance operational efficiency and product integrity.

Air Compressor Used in the Food & Beverage Industry?

Pneumatic Conveying

Air compressors power pneumatic conveying systems used to transport ingredients, powders, and granules throughout the production process.

It enables efficient material handling, reducing manual labor and streamlining operations.

Packaging and Bottling

Air compressors drive pneumatic machinery for packaging and bottling operations, including filling, capping, labeling, and sealing.

The consistent and reliable airflow provided by screw air compressors ensures precise and hygienic packaging of food and beverage products.

Cleaning and Sanitization

Compressed air is utilized for cleaning and sanitizing equipment, containers, and production areas. Air-powered cleaning systems effectively remove debris, residues, and contaminants, maintaining stringent hygiene standards required in the food industry.

Food Processing Equipment

Air compressors supply power to pneumatic tools and machinery used in food processing, such as mixers, blenders, and extruders.

These tools facilitate the mixing, blending, and shaping of ingredients, ensuring uniform product quality and consistency.

Controlled Atmosphere Storage

In the beverage industry, air compressors are employed to create controlled atmospheres in storage facilities, such as wine cellars and breweries.

By regulating temperature, humidity, and air quality, compressors help preserve the flavor, aroma, and quality of beverages during storage.

Nitrogen Generation

Some food and beverage production processes require the use of nitrogen gas for packaging and preservation.

Air compressors can be integrated with nitrogen generation systems to produce high-purity nitrogen onsite, eliminating the need for external nitrogen cylinders and ensuring product freshness and shelf life.

Compliance with Standards

Air compressors used in the food and beverage industry must adhere to strict regulatory standards for air quality and hygiene.

Oil-free compressors are often preferred to prevent contamination, while compressed air filter systems remove impurities and moisture from compressed air, ensuring compliance with food safety regulations.

Variable Speed Compressors

By employing variable speed drive technology, these compressors optimize energy consumption by adjusting the motor’s speed according to the air demand.

Oil-free Compressors

Oil free air compressors provide high-quality compressed air free from oil contamination, ensuring the integrity of sensitive processes and applications.

Refrigerated Air Dryers

Air dryers are responsible for removing moisture and contaminants, ensuring clean and dry air for various applications.

Selecting the Right Air Compressor

In the food and beverage industry, where hygiene, safety, and efficiency are paramoun.

Oil-Free Operation

Opt for oil-free air compressors to prevent contamination of food and beverage products. Oil-free compressors eliminate the risk of oil carryover into the compressed air stream, ensuring purity and compliance with food safety standards.

Food-Grade Materials

Select air compressors constructed from food-grade materials to minimize the risk of product contamination.

Stainless steel or aluminum components are ideal choices as they are corrosion-resistant and easy to clean, maintaining hygiene standards in food processing environments.

Hygienic Design

Look for air compressors with hygienic designs that minimize the accumulation of dirt, moisture, and bacteria.

Sealed enclosures, smooth surfaces, and sanitary fittings facilitate easy cleaning and sanitation, reducing the risk of microbial growth and ensuring product safety.

Compliance with Regulations

Ensure that the selected air compressor complies with relevant regulatory standards for air quality, safety, and hygiene.

Compressors should meet specifications such as ISO 8573-1 certification for air purity and adhere to guidelines set forth by regulatory bodies like the Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA).

Energy Efficiency

Choose energy-efficient air compressors equipped with variable speed drives (VSD) or energy-saving features to minimize operating costs and environmental impact.

Energy-efficient compressors help optimize energy consumption, reduce carbon footprint, and enhance sustainability in food and beverage production facilities.

Capacity and Pressure

Consider the specific air quality requirements and demand levels of food and beverage production processes.

Determine the required air pressure, flow rate, and purity levels to select an air compressor with the appropriate capacity and filtration systems to meet production needs effectively.

For example, bottle blowing require compressors with a working pressure of 30 – 40 bar.

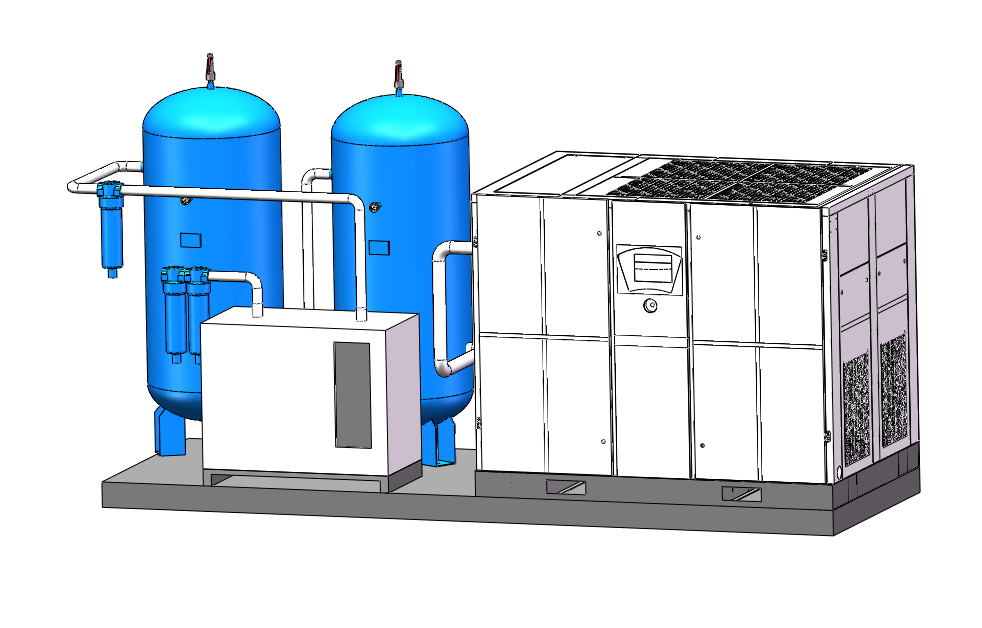

Compressed Air System Design

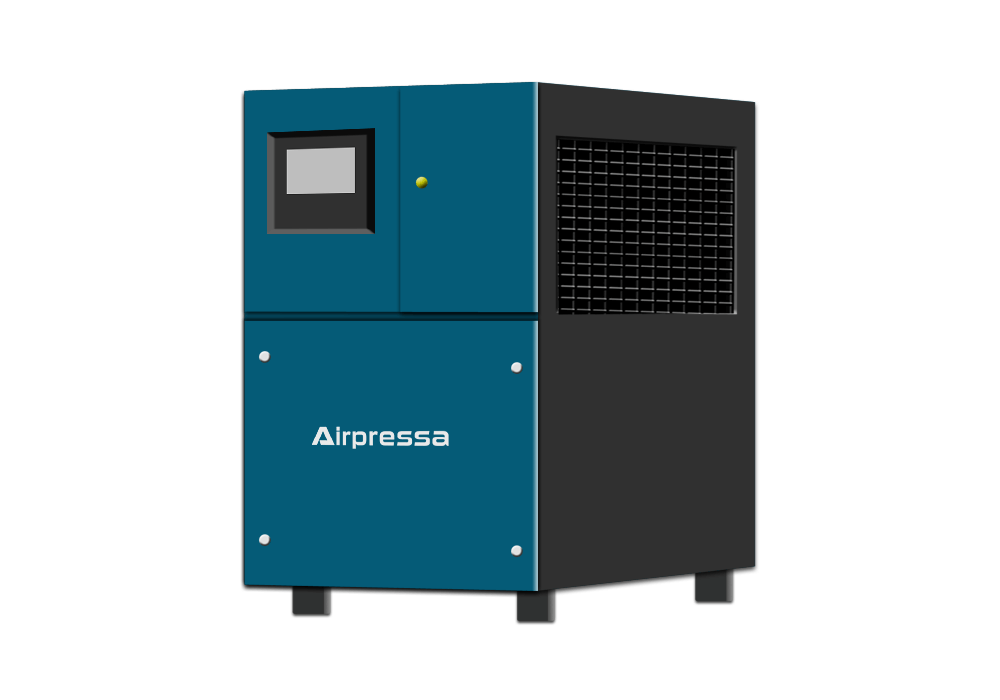

1. Air Compressor

2. Air Dryer

3. Air Receiver Tank

4. Air Filters

5. Air Intake Filter

6. Pipes and Connections

Get Expert Support

Choose Airpressa for all your compressed air needs and experience the benefits of working with a reliable, professional, and customer-focused manufacturer.