Screw Oil Free Air Compressors for Sale

Why Airpressa’s Rotary Screw Oil Free Air Compressors?

Production History of Airpressa’s Oil Free Air Compressors

At Airpressa, we are dedicated to providing reliable, efficient, and cost-effective rotary screw oil free air compressors that meet the diverse needs of industries worldwide.

With a manufacturing history spanning over two decades since our establishment in the year 2000, Airpressa has a proven track record as a reliable Chinese manufacturer of rotary screw oil free air compressors.

Our extensive experience in the industry has allowed us to refine our production processes, ensuring the delivery of high-quality and durable compressors that meet the stringent requirements of various applications.

Design of Airpressa’s Screw-Type Oil Free Air Compressors

Airpressa takes great care in the design of our screw-type oil free air compressors. We employ advanced engineering techniques and cutting-edge technology to create compressors that are efficient, reliable, and oil-free.

Our compressors are meticulously crafted to eliminate the risk of oil contamination, guaranteeing clean and uncontaminated compressed air for critical industries such as pharmaceutical manufacturing, electronics assembly, and food processing.

Energy Efficiency of Airpressa’s Variable Speed Screw Oil Free Air Compressors

Airpressa takes pride in producing variable speed air compressors with oil free option, that excel in energy efficiency. By incorporating variable speed drive technology, our compressors are designed to match the compressed air demand with the precise power required, resulting in significant energy savings.

This not only reduces operating costs but also minimizes the environmental impact, making our compressors a sustainable choice for businesses aiming to optimize energy consumption.

High-Quality and Cost-Effective Rotary Screw Oil Free Air Compressors

At Airpressa, we are committed to delivering high-quality compressors at competitive prices, providing our customers with exceptional value for their investment.

Our rotary screw oil free air compressors are renowned for their reliability, durability, and performance, all while maintaining an affordable price point. We believe in offering a cost-effective solution without compromising on the quality and functionality of our products.

Airpressa’s Rotary Screw Oil Free Air Compressors

Fixed Speed & Variable Speed

7.5 - 22 KW (10 - 30 HP)

Water Lubricated

Fixed Speed & Variable Speed

Pressure: 7/8/10 bar

Flow: 1.1 – 3.7 m3/min

Intelligent Control

Direct Drive

Protection IP23/IP55

LEARN MORE

30 - 55 KW (40 - 75 HP)

Water Lubricated & Dry Oil-Free

Fixed Speed & Variable Speed

Pressure: 7/8/10 bar

Flow: 4.3 – 10.0 m3/min

Intelligent Control

Direct Drive

Protection IP23/IP55

LEARN MORE

75 - 132 KW (100 - 175 HP)

Water Lubricated & Dry Oil-free

Fixed Speed & Variable Speed

Pressure: 7/8/10 bar

Flow: 10.0 – 25.0 m3/min

Intelligent Control

Direct Drive

Protection IP23/IP55

LEARN MORE

160 - 250 KW (215 - 350 HP)

Water Lubricated & Dry Oil-free

Fixed Speed & Variable Speed

Pressure: 7/8/10 bar

Flow: 24.0-43.0 m3/min

Intelligent Control

Direct Drive

Protection IP23/IP55

LEARN MORE

Water Lubricated VS Dry Oil Free Air Compressors

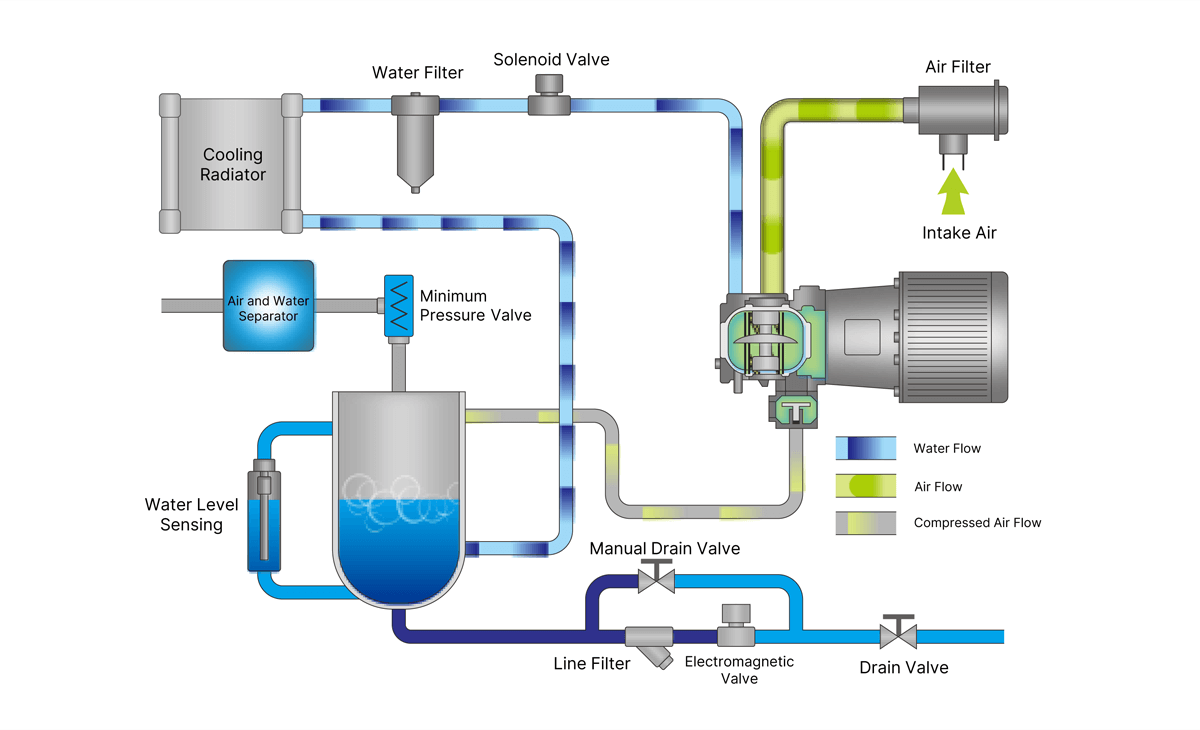

Oil-free air compressors include two main types: water lubricated and dry oil free air compressors.

Water lubricated compressors use water as a lubricant and coolant, eliminating the need for oil. Dry oil free compressors utilize advanced materials and coatings to eliminate the need for lubrication altogether.

While both types offer oil-free compressed air, the choice between them depends on factors such as the required air quality, operating conditions, and specific application requirements.

Advantages of Rotary Screw Oil Free Air Compressors

Firstly, Oil free air compressors provide high-quality compressed air free from oil contamination, ensuring the integrity of sensitive processes and applications.

Secondly, these compressors are energy-efficient, resulting in cost savings and reduced environmental impact. They also feature quiet operation and compact designs, making them suitable for installations in noise-sensitive environments or where space is limited.

Key Factors to Selecting the Best Rotary Screw Oil Free Air Compressors

Selecting the optimal rotary screw oil free air compressor involves considering several important factors. These factors include the required airflow and pressure, duty cycle, ambient conditions, power source availability, and specific application requirements.

Additionally, factors such as compressor reliability, energy efficiency, ease of maintenance. By carefully evaluating these factors, you can choose a oil free air compressor that matches your needs and provides reliable performance.

Applications of Rotary Screw Oil Free Air Compressors

Pharmaceutical Industry

Rotary screw oil free air compressors are crucial in pharmaceutical manufacturing processes, where clean and contaminant-free compressed air is essential for maintaining product integrity and complying with strict quality standards.

Food and Beverage Industry

Oil free air compressors find extensive usage in the food and beverage industry, providing oil-free compressed air for processes such as product packaging, bottling, filling, and pneumatic conveying, ensuring food safety and preventing product contamination.

Electronics Industry

In the electronics industry, where precision and cleanliness are paramount, rotary screw oil free air compressors are employed in applications such as semiconductor manufacturing, printed circuit board assembly, and electronic component production.

Automotive Industry

Oil-free air compressors play a significant role in automotive manufacturing, where they are utilized in various processes, including painting, pneumatic tool operation, and operating air-driven control systems.

Textile Industry

Rotary screw oil free air compressors are used in textile manufacturing processes, such as spinning, weaving, and dyeing. They provide clean and oil-free compressed air for powering pneumatic machinery and maintaining product quality.

Medical and Healthcare Facilities

Hospitals, clinics, and medical laboratories rely on oil-free air compressors to provide clean compressed air for medical equipment, dental tools, and surgical instruments, ensuring a sterile environment and patient safety.

Research and Development Facilities

In research and development laboratories, where precision and accuracy are crucial, oil-free air compressors are used for various applications, including testing, calibration, and operating sensitive instrumentation.

Packaging Industry

Rotary screw oil free air compressors find extensive usage in the packaging industry for applications like sealing, labeling, and operating pneumatic packaging machinery, ensuring product integrity and efficiency.

Printing Industry

Oil-free air compressors are essential in the printing industry, where they are used for applications such as operating printing presses, paper handling, and maintaining consistent ink quality.

Environmental and Water Treatment

These compressors play a role in environmental and water treatment applications, providing oil-free compressed air for aeration, wastewater treatment, and air pollution control processes.

Maintenance for Rotary Screw Oil Free Air Compressors

Proper maintenance and care are essential for the optimal performance and longevity of rotary screw oil free air compressors.

Regular maintenance tasks include checking and replacing filters, monitoring oil levels in the drive system (if applicable), inspecting and tightening connections, and inspecting the cooling system.

It is also crucial to follow the manufacturer’s guidelines for maintenance intervals and recommended lubricants (if applicable). By adhering to a proactive maintenance routine, you can minimize downtime, extend the lifespan of the compressor, and ensure consistent and reliable operation.

A LEADING MANUFACTURER OF

ROTARY SCREW AIR COMPRESSORS

Airpressa is a leading manufacturer, exporter, and solution provider of industrial air compressors in China. With a rich history dating back to the year 2000, we have been consistently delivering high-quality air compressors and related products to meet the diverse needs of our global clients.

At Airpressa, we are not just about manufacturing air compressors. We are also a trusted partner and solution provider for our clients. We work closely with them to understand their unique requirements and offer customized solutions to meet their specific needs.